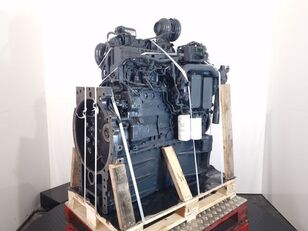

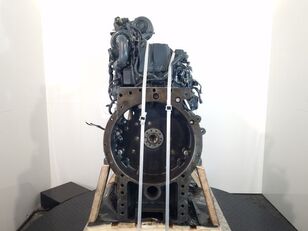

Двигател Caterpillar MWM за Caterpillar MWM TCG2020V16

Ако сте решили да купувате техника на ниска цена, уверете се, че общувате с реален продавач. Съберете колкото се може повече информация за собственика на техниката. Един от начините за измама е да се представяш за реално съществуваща фирма. Ако имате някакви подозрения, съобщете ни за това за допълнителен контрол с помощта на формуляра за обратна връзка.

Преди да решите да купите нещо, внимателно проверете няколко оферти за продажба, за да разберете средната стойност на избрания от вас модел на техниката. Ако цената на офертата, която сте си харесали е много по-ниска от подобните оферти, не бързайте, помислете. Значителната разлика в цената може да означава скрити дефекти или опит на продавача да извърши мошенически действия.

Не купувайте стоки, цената на които прекалено много се различава от средната цена на подобна техника.

Не давайте съгласие за съмнителни залози и авансово плащане на стоката. Ако имате някакви съмнения, не се страхувайте да уточнявате подробностите, искайте допълнителни снимки и документи на техниката, проверявайте достоверността на документите, задавайте въпроси.

Това е най-разпространеният вид мошеничество. Нечестните продавачи могат да поискат определен аванс за „резервиране” на правото ви за закупуване на техниката. По този начин мошениците могат да съберат голяма сума пари, да изчезнат и да не отговарят повече.

- Превод на авансовото плащане по карта

- Не внасяйте авансовото плащане без да оформите документи, потвърждаващи процеса на предаване на парите, ако при общуването ви с продавача той предизвиква съмнения.

- Превод по сметка на фирма с подобно име

- Бъдете внимателни, мошениците могат да се маскират като известни фирми чрез незначителни промени в названието. Не превеждайте пари, ако названието на фирмата предизвиква съмнения.

- Превод по сметка на фирма с подобно име

- Бъдете внимателни, мошениците могат да се маскират като известни фирми чрез незначителни промени в названието. Не превеждайте пари, ако названието на фирмата предизвиква съмнения.

- Въвеждане на собствени реквизити във фактура на реална фирма

- Преди да преведете парите, проверете дали посочените реквизити са правилни и дали те се отнасят към посочената фирма.

Информация за контакт с продавача

Австрия

Австрия

el.power 1560kW 10500V 50Hz new TPEM

heat utilization temp.power 1597kW

alternator Marelli MJH560LA4 or similar

Genset MWM TCG2020 V16

Technical data

1560 kWel; 10500 V, 50 Hz; Natural gas, MN = 80

Engine / Configuration code:

TCG 2020 V16

R

Speed / Mean piston speed:

[1/min] / [m/s]

1500 / 9.8

Configuration / number of cylinders:

[ - ]

V / 16

Bore / Stroke / Displacement:

[mm]/[mm]/[dm3]

170 / 195 / 71

Compression ratio:

[ - ]

13

Mean effective pressure:

[bar]

18,2

Mean lube oil consumption at full load:

[g/kWh]

0,15

Generator:

Marelli MJH 560 LA4 or similar (*)

Voltage / voltage range / cos Phi:

[V] / [%] / [-]

10500 / 10 / 1

Speed / frequency:

[1/min] / [Hz]

1500 / 50

Engine Parts

3

Engine configuration

3

Basic parts

3

Exhaust gas system

3

Exhaust Gas Outlet vertical

3

Exhaust turbo charger

3

Gas mixture pipe

3

Cooling system on cylinder rows A or B, horizontal

3

Torsional vibration damper

3

Fly wheel

3

Fly wheel casing

3

Starter equipment, electric with double starter and temperature cut-off

3

Engine Mounting

3

Lube oil system

3

Gas mixer

3

Suction system Standard

3

Crankcase ventilation

3

Primer and Topcoat Engine - Primer

3

Conservation

Exhaust Gas Outlet

3

Exhaust Gas Outlet vertical

Engine Control

3

Control without ExhaustTurboCharger speed monitoring / without control exhaust wastegate

Pre-Lubrication

3

Pre lubrication 230 / 400 / 460 V

Engine Test

3

Engine acceptance test without customer participation

Tools for commissioning and assembling

1

Tool Kit small scope for commissioning and assembling

Spare Parts for New Engines

3

without spare parts for new installation

Genset Parts

3

Genset defintion

3

Generator - Marelli - MJH 560 LA4

3

Base frame with integrated oil tank

3

Elastic genset mounting

3

Elastic coupling

3

Fasteners

3

Crankcase ventilation

3

Pre Lubrication Genset - V

3

Lubeoil level monitoring

3

Additional parts for lubrication system 230 V/50 / 60 Hz

3

Warning sign for oil cooler

3

Suction pipe

3

Air filter with air preheating

3

Water circuit components for air preheating

Primer and Topcoat for Genset

3

Primer and Topcoat for Genset - RAL 5010, gentian blue

Name Plates for Complete Engine

3

Name Plates for Aggregate in Russian

Fuel System

Zero-Pressure Gas Control Train

3

Gas train DN 65/65/65 - with seal monitoring unit

Connecting Accessories for Zero Pressure Train

3

Compensator for gasconnection

3

Connection Accessories for Gas Train DN 65 - Steel

Electrical Preheating

3

Electric Preheating - 400 / 480 V / 9 kW / with flanges

3

Counter Flange Set DN 80

Sensors

3

Exhaust back pressure sensor

Genset Management (TEM)

Base System

3

TEM - Basic Cabinet (ST20F-F)

3

TEM packaging in wooden crate (VER)

Power Plant Control System

3

Inlet air preheating (AVW)

Interface

3

Modbus RTU (MRTU)

3

Analog speed setting (ASD)

Hardware

3

I/O Controller (IOC) (included in Base system)

3

Operating terminal (BRT)

3

wall switch cabinet, Height 1200mm door hinge right (AE0R)

3

Console (KBW)

3

Cable entry from above (KEO)

3

TEM connecting cable set 15m (K20ARM15)

Documentation

3

Documentation first language - standard documentation

el.power 1560kW 10500V 50Hz new TPEM

heat utilization temp.power 1597kW

alternator Marelli MJH560LA4 or similar

Genset MWM TCG2020 V16

Technical data

1560 kWel; 10500 V, 50 Hz; Natural gas, MN = 80

Engine / Configuration code:

TCG 2020 V16

R

Speed / Mean piston speed:

[1/min] / [m/s]

1500 / 9.8

Configuration / number of cylinders:

[ - ]

V / 16

Bore / Stroke / Displacement:

[mm]/[mm]/[dm3]

170 / 195 / 71

Compression ratio:

[ - ]

13

Mean effective pressure:

[bar]

18,2

Mean lube oil consumption at full load:

[g/kWh]

0,15

Generator:

Marelli MJH 560 LA4 or similar (*)

Voltage / voltage range / cos Phi:

[V] / [%] / [-]

10500 / 10 / 1

Speed / frequency:

[1/min] / [Hz]

1500 / 50

Engine Parts

3

Engine configuration

3

Basic parts

3

Exhaust gas system

3

Exhaust Gas Outlet vertical

3

Exhaust turbo charger

3

Gas mixture pipe

3

Cooling system on cylinder rows A or B, horizontal

3

Torsional vibration damper

3

Fly wheel

3

Fly wheel casing

3

Starter equipment, electric with double starter and temperature cut-off

3

Engine Mounting

3

Lube oil system

3

Gas mixer

3

Suction system Standard

3

Crankcase ventilation

3

Primer and Topcoat Engine - Primer

3

Conservation

Exhaust Gas Outlet

3

Exhaust Gas Outlet vertical

Engine Control

3

Control without ExhaustTurboCharger speed monitoring / without control exhaust wastegate

Pre-Lubrication

3

Pre lubrication 230 / 400 / 460 V

Engine Test

3

Engine acceptance test without customer participation

Tools for commissioning and assembling

1

Tool Kit small scope for commissioning and assembling

Spare Parts for New Engines

3

without spare parts for new installation

Genset Parts

3

Genset defintion

3

Generator - Marelli - MJH 560 LA4

3

Base frame with integrated oil tank

3

Elastic genset mounting

3

Elastic coupling

3

Fasteners

3

Crankcase ventilation

3

Pre Lubrication Genset - V

3

Lubeoil level monitoring

3

Additional parts for lubrication system 230 V/50 / 60 Hz

3

Warning sign for oil cooler

3

Suction pipe

3

Air filter with air preheating

3

Water circuit components for air preheating

Primer and Topcoat for Genset

3

Primer and Topcoat for Genset - RAL 5010, gentian blue

Name Plates for Complete Engine

3

Name Plates for Aggregate in Russian

Fuel System

Zero-Pressure Gas Control Train

3

Gas train DN 65/65/65 - with seal monitoring unit

Connecting Accessories for Zero Pressure Train

3

Compensator for gasconnection

3

Connection Accessories for Gas Train DN 65 - Steel

Electrical Preheating

3

Electric Preheating - 400 / 480 V / 9 kW / with flanges

3

Counter Flange Set DN 80

Sensors

3

Exhaust back pressure sensor

Genset Management (TEM)

Base System

3

TEM - Basic Cabinet (ST20F-F)

3

TEM packaging in wooden crate (VER)

Power Plant Control System

3

Inlet air preheating (AVW)

Interface

3

Modbus RTU (MRTU)

3

Analog speed setting (ASD)

Hardware

3

I/O Controller (IOC) (included in Base system)

3

Operating terminal (BRT)

3

wall switch cabinet, Height 1200mm door hinge right (AE0R)

3

Console (KBW)

3

Cable entry from above (KEO)

3

TEM connecting cable set 15m (K20ARM15)

Documentation

3

Documentation first language - standard documentation

el.power 1560kW 10500V 50Hz new TPEM

heat utilization temp.power 1597kW

alternator Marelli MJH560LA4 or similar

Genset MWM TCG2020 V16

Technical data

1560 kWel; 10500 V, 50 Hz; Natural gas, MN = 80

Engine / Configuration code:

TCG 2020 V16

R

Speed / Mean piston speed:

[1/min] / [m/s]

1500 / 9.8

Configuration / number of cylinders:

[ - ]

V / 16

Bore / Stroke / Displacement:

[mm]/[mm]/[dm3]

170 / 195 / 71

Compression ratio:

[ - ]

13

Mean effective pressure:

[bar]

18,2

Mean lube oil consumption at full load:

[g/kWh]

0,15

Generator:

Marelli MJH 560 LA4 or similar (*)

Voltage / voltage range / cos Phi:

[V] / [%] / [-]

10500 / 10 / 1

Speed / frequency:

[1/min] / [Hz]

1500 / 50

Engine Parts

3

Engine configuration

3

Basic parts

3

Exhaust gas system

3

Exhaust Gas Outlet vertical

3

Exhaust turbo charger

3

Gas mixture pipe

3

Cooling system on cylinder rows A or B, horizontal

3

Torsional vibration damper

3

Fly wheel

3

Fly wheel casing

3

Starter equipment, electric with double starter and temperature cut-off

3

Engine Mounting

3

Lube oil system

3

Gas mixer

3

Suction system Standard

3

Crankcase ventilation

3

Primer and Topcoat Engine - Primer

3

Conservation

Exhaust Gas Outlet

3

Exhaust Gas Outlet vertical

Engine Control

3

Control without ExhaustTurboCharger speed monitoring / without control exhaust wastegate

Pre-Lubrication

3

Pre lubrication 230 / 400 / 460 V

Engine Test

3

Engine acceptance test without customer participation

Tools for commissioning and assembling

1

Tool Kit small scope for commissioning and assembling

Spare Parts for New Engines

3

without spare parts for new installation

Genset Parts

3

Genset defintion

3

Generator - Marelli - MJH 560 LA4

3

Base frame with integrated oil tank

3

Elastic genset mounting

3

Elastic coupling

3

Fasteners

3

Crankcase ventilation

3

Pre Lubrication Genset - V

3

Lubeoil level monitoring

3

Additional parts for lubrication system 230 V/50 / 60 Hz

3

Warning sign for oil cooler

3

Suction pipe

3

Air filter with air preheating

3

Water circuit components for air preheating

Primer and Topcoat for Genset

3

Primer and Topcoat for Genset - RAL 5010, gentian blue

Name Plates for Complete Engine

3

Name Plates for Aggregate in Russian

Fuel System

Zero-Pressure Gas Control Train

3

Gas train DN 65/65/65 - with seal monitoring unit

Connecting Accessories for Zero Pressure Train

3

Compensator for gasconnection

3

Connection Accessories for Gas Train DN 65 - Steel

Electrical Preheating

3

Electric Preheating - 400 / 480 V / 9 kW / with flanges

3

Counter Flange Set DN 80

Sensors

3

Exhaust back pressure sensor

Genset Management (TEM)

Base System

3

TEM - Basic Cabinet (ST20F-F)

3

TEM packaging in wooden crate (VER)

Power Plant Control System

3

Inlet air preheating (AVW)

Interface

3

Modbus RTU (MRTU)

3

Analog speed setting (ASD)

Hardware

3

I/O Controller (IOC) (included in Base system)

3

Operating terminal (BRT)

3

wall switch cabinet, Height 1200mm door hinge right (AE0R)

3

Console (KBW)

3

Cable entry from above (KEO)

3

TEM connecting cable set 15m (K20ARM15)

Documentation

3

Documentation first language - standard documentation

el.power 1560kW 10500V 50Hz new TPEM

heat utilization temp.power 1597kW

alternator Marelli MJH560LA4 or similar

Genset MWM TCG2020 V16

Technical data

1560 kWel; 10500 V, 50 Hz; Natural gas, MN = 80

Engine / Configuration code:

TCG 2020 V16

R

Speed / Mean piston speed:

[1/min] / [m/s]

1500 / 9.8

Configuration / number of cylinders:

[ - ]

V / 16

Bore / Stroke / Displacement:

[mm]/[mm]/[dm3]

170 / 195 / 71

Compression ratio:

[ - ]

13

Mean effective pressure:

[bar]

18,2

Mean lube oil consumption at full load:

[g/kWh]

0,15

Generator:

Marelli MJH 560 LA4 or similar (*)

Voltage / voltage range / cos Phi:

[V] / [%] / [-]

10500 / 10 / 1

Speed / frequency:

[1/min] / [Hz]

1500 / 50

Engine Parts

3

Engine configuration

3

Basic parts

3

Exhaust gas system

3

Exhaust Gas Outlet vertical

3

Exhaust turbo charger

3

Gas mixture pipe

3

Cooling system on cylinder rows A or B, horizontal

3

Torsional vibration damper

3

Fly wheel

3

Fly wheel casing

3

Starter equipment, electric with double starter and temperature cut-off

3

Engine Mounting

3

Lube oil system

3

Gas mixer

3

Suction system Standard

3

Crankcase ventilation

3

Primer and Topcoat Engine - Primer

3

Conservation

Exhaust Gas Outlet

3

Exhaust Gas Outlet vertical

Engine Control

3

Control without ExhaustTurboCharger speed monitoring / without control exhaust wastegate

Pre-Lubrication

3

Pre lubrication 230 / 400 / 460 V

Engine Test

3

Engine acceptance test without customer participation

Tools for commissioning and assembling

1

Tool Kit small scope for commissioning and assembling

Spare Parts for New Engines

3

without spare parts for new installation

Genset Parts

3

Genset defintion

3

Generator - Marelli - MJH 560 LA4

3

Base frame with integrated oil tank

3

Elastic genset mounting

3

Elastic coupling

3

Fasteners

3

Crankcase ventilation

3

Pre Lubrication Genset - V

3

Lubeoil level monitoring

3

Additional parts for lubrication system 230 V/50 / 60 Hz

3

Warning sign for oil cooler

3

Suction pipe

3

Air filter with air preheating

3

Water circuit components for air preheating

Primer and Topcoat for Genset

3

Primer and Topcoat for Genset - RAL 5010, gentian blue

Name Plates for Complete Engine

3

Name Plates for Aggregate in Russian

Fuel System

Zero-Pressure Gas Control Train

3

Gas train DN 65/65/65 - with seal monitoring unit

Connecting Accessories for Zero Pressure Train

3

Compensator for gasconnection

3

Connection Accessories for Gas Train DN 65 - Steel

Electrical Preheating

3

Electric Preheating - 400 / 480 V / 9 kW / with flanges

3

Counter Flange Set DN 80

Sensors

3

Exhaust back pressure sensor

Genset Management (TEM)

Base System

3

TEM - Basic Cabinet (ST20F-F)

3

TEM packaging in wooden crate (VER)

Power Plant Control System

3

Inlet air preheating (AVW)

Interface

3

Modbus RTU (MRTU)

3

Analog speed setting (ASD)

Hardware

3

I/O Controller (IOC) (included in Base system)

3

Operating terminal (BRT)

3

wall switch cabinet, Height 1200mm door hinge right (AE0R)

3

Console (KBW)

3

Cable entry from above (KEO)

3

TEM connecting cable set 15m (K20ARM15)

Documentation

3

Documentation first language - standard documentation

el.power 1560kW 10500V 50Hz new TPEM

heat utilization temp.power 1597kW

alternator Marelli MJH560LA4 or similar

Genset MWM TCG2020 V16

Technical data

1560 kWel; 10500 V, 50 Hz; Natural gas, MN = 80

Engine / Configuration code:

TCG 2020 V16

R

Speed / Mean piston speed:

[1/min] / [m/s]

1500 / 9.8

Configuration / number of cylinders:

[ - ]

V / 16

Bore / Stroke / Displacement:

[mm]/[mm]/[dm3]

170 / 195 / 71

Compression ratio:

[ - ]

13

Mean effective pressure:

[bar]

18,2

Mean lube oil consumption at full load:

[g/kWh]

0,15

Generator:

Marelli MJH 560 LA4 or similar (*)

Voltage / voltage range / cos Phi:

[V] / [%] / [-]

10500 / 10 / 1

Speed / frequency:

[1/min] / [Hz]

1500 / 50

Engine Parts

3

Engine configuration

3

Basic parts

3

Exhaust gas system

3

Exhaust Gas Outlet vertical

3

Exhaust turbo charger

3

Gas mixture pipe

3

Cooling system on cylinder rows A or B, horizontal

3

Torsional vibration damper

3

Fly wheel

3

Fly wheel casing

3

Starter equipment, electric with double starter and temperature cut-off

3

Engine Mounting

3

Lube oil system

3

Gas mixer

3

Suction system Standard

3

Crankcase ventilation

3

Primer and Topcoat Engine - Primer

3

Conservation

Exhaust Gas Outlet

3

Exhaust Gas Outlet vertical

Engine Control

3

Control without ExhaustTurboCharger speed monitoring / without control exhaust wastegate

Pre-Lubrication

3

Pre lubrication 230 / 400 / 460 V

Engine Test

3

Engine acceptance test without customer participation

Tools for commissioning and assembling

1

Tool Kit small scope for commissioning and assembling

Spare Parts for New Engines

3

without spare parts for new installation

Genset Parts

3

Genset defintion

3

Generator - Marelli - MJH 560 LA4

3

Base frame with integrated oil tank

3

Elastic genset mounting

3

Elastic coupling

3

Fasteners

3

Crankcase ventilation

3

Pre Lubrication Genset - V

3

Lubeoil level monitoring

3

Additional parts for lubrication system 230 V/50 / 60 Hz

3

Warning sign for oil cooler

3

Suction pipe

3

Air filter with air preheating

3

Water circuit components for air preheating

Primer and Topcoat for Genset

3

Primer and Topcoat for Genset - RAL 5010, gentian blue

Name Plates for Complete Engine

3

Name Plates for Aggregate in Russian

Fuel System

Zero-Pressure Gas Control Train

3

Gas train DN 65/65/65 - with seal monitoring unit

Connecting Accessories for Zero Pressure Train

3

Compensator for gasconnection

3

Connection Accessories for Gas Train DN 65 - Steel

Electrical Preheating

3

Electric Preheating - 400 / 480 V / 9 kW / with flanges

3

Counter Flange Set DN 80

Sensors

3

Exhaust back pressure sensor

Genset Management (TEM)

Base System

3

TEM - Basic Cabinet (ST20F-F)

3

TEM packaging in wooden crate (VER)

Power Plant Control System

3

Inlet air preheating (AVW)

Interface

3

Modbus RTU (MRTU)

3

Analog speed setting (ASD)

Hardware

3

I/O Controller (IOC) (included in Base system)

3

Operating terminal (BRT)

3

wall switch cabinet, Height 1200mm door hinge right (AE0R)

3

Console (KBW)

3

Cable entry from above (KEO)

3

TEM connecting cable set 15m (K20ARM15)

Documentation

3

Documentation first language - standard documentation

el.power 1560kW 10500V 50Hz new TPEM

heat utilization temp.power 1597kW

alternator Marelli MJH560LA4 or similar

Genset MWM TCG2020 V16

Technical data

1560 kWel; 10500 V, 50 Hz; Natural gas, MN = 80

Engine / Configuration code:

TCG 2020 V16

R

Speed / Mean piston speed:

[1/min] / [m/s]

1500 / 9.8

Configuration / number of cylinders:

[ - ]

V / 16

Bore / Stroke / Displacement:

[mm]/[mm]/[dm3]

170 / 195 / 71

Compression ratio:

[ - ]

13

Mean effective pressure:

[bar]

18,2

Mean lube oil consumption at full load:

[g/kWh]

0,15

Generator:

Marelli MJH 560 LA4 or similar (*)

Voltage / voltage range / cos Phi:

[V] / [%] / [-]

10500 / 10 / 1

Speed / frequency:

[1/min] / [Hz]

1500 / 50

Engine Parts

3

Engine configuration

3

Basic parts

3

Exhaust gas system

3

Exhaust Gas Outlet vertical

3

Exhaust turbo charger

3

Gas mixture pipe

3

Cooling system on cylinder rows A or B, horizontal

3

Torsional vibration damper

3

Fly wheel

3

Fly wheel casing

3

Starter equipment, electric with double starter and temperature cut-off

3

Engine Mounting

3

Lube oil system

3

Gas mixer

3

Suction system Standard

3

Crankcase ventilation

3

Primer and Topcoat Engine - Primer

3

Conservation

Exhaust Gas Outlet

3

Exhaust Gas Outlet vertical

Engine Control

3

Control without ExhaustTurboCharger speed monitoring / without control exhaust wastegate

Pre-Lubrication

3

Pre lubrication 230 / 400 / 460 V

Engine Test

3

Engine acceptance test without customer participation

Tools for commissioning and assembling

1

Tool Kit small scope for commissioning and assembling

Spare Parts for New Engines

3

without spare parts for new installation

Genset Parts

3

Genset defintion

3

Generator - Marelli - MJH 560 LA4

3

Base frame with integrated oil tank

3

Elastic genset mounting

3

Elastic coupling

3

Fasteners

3

Crankcase ventilation

3

Pre Lubrication Genset - V

3

Lubeoil level monitoring

3

Additional parts for lubrication system 230 V/50 / 60 Hz

3

Warning sign for oil cooler

3

Suction pipe

3

Air filter with air preheating

3

Water circuit components for air preheating

Primer and Topcoat for Genset

3

Primer and Topcoat for Genset - RAL 5010, gentian blue

Name Plates for Complete Engine

3

Name Plates for Aggregate in Russian

Fuel System

Zero-Pressure Gas Control Train

3

Gas train DN 65/65/65 - with seal monitoring unit

Connecting Accessories for Zero Pressure Train

3

Compensator for gasconnection

3

Connection Accessories for Gas Train DN 65 - Steel

Electrical Preheating

3

Electric Preheating - 400 / 480 V / 9 kW / with flanges

3

Counter Flange Set DN 80

Sensors

3

Exhaust back pressure sensor

Genset Management (TEM)

Base System

3

TEM - Basic Cabinet (ST20F-F)

3

TEM packaging in wooden crate (VER)

Power Plant Control System

3

Inlet air preheating (AVW)

Interface

3

Modbus RTU (MRTU)

3

Analog speed setting (ASD)

Hardware

3

I/O Controller (IOC) (included in Base system)

3

Operating terminal (BRT)

3

wall switch cabinet, Height 1200mm door hinge right (AE0R)

3

Console (KBW)

3

Cable entry from above (KEO)

3

TEM connecting cable set 15m (K20ARM15)

Documentation

3

Documentation first language - standard documentation

el.power 1560kW 10500V 50Hz new TPEM

heat utilization temp.power 1597kW

alternator Marelli MJH560LA4 or similar

Genset MWM TCG2020 V16

Technical data

1560 kWel; 10500 V, 50 Hz; Natural gas, MN = 80

Engine / Configuration code:

TCG 2020 V16

R

Speed / Mean piston speed:

[1/min] / [m/s]

1500 / 9.8

Configuration / number of cylinders:

[ - ]

V / 16

Bore / Stroke / Displacement:

[mm]/[mm]/[dm3]

170 / 195 / 71

Compression ratio:

[ - ]

13

Mean effective pressure:

[bar]

18,2

Mean lube oil consumption at full load:

[g/kWh]

0,15

Generator:

Marelli MJH 560 LA4 or similar (*)

Voltage / voltage range / cos Phi:

[V] / [%] / [-]

10500 / 10 / 1

Speed / frequency:

[1/min] / [Hz]

1500 / 50

Engine Parts

3

Engine configuration

3

Basic parts

3

Exhaust gas system

3

Exhaust Gas Outlet vertical

3

Exhaust turbo charger

3

Gas mixture pipe

3

Cooling system on cylinder rows A or B, horizontal

3

Torsional vibration damper

3

Fly wheel

3

Fly wheel casing

3

Starter equipment, electric with double starter and temperature cut-off

3

Engine Mounting

3

Lube oil system

3

Gas mixer

3

Suction system Standard

3

Crankcase ventilation

3

Primer and Topcoat Engine - Primer

3

Conservation

Exhaust Gas Outlet

3

Exhaust Gas Outlet vertical

Engine Control

3

Control without ExhaustTurboCharger speed monitoring / without control exhaust wastegate

Pre-Lubrication

3

Pre lubrication 230 / 400 / 460 V

Engine Test

3

Engine acceptance test without customer participation

Tools for commissioning and assembling

1

Tool Kit small scope for commissioning and assembling

Spare Parts for New Engines

3

without spare parts for new installation

Genset Parts

3

Genset defintion

3

Generator - Marelli - MJH 560 LA4

3

Base frame with integrated oil tank

3

Elastic genset mounting

3

Elastic coupling

3

Fasteners

3

Crankcase ventilation

3

Pre Lubrication Genset - V

3

Lubeoil level monitoring

3

Additional parts for lubrication system 230 V/50 / 60 Hz

3

Warning sign for oil cooler

3

Suction pipe

3

Air filter with air preheating

3

Water circuit components for air preheating

Primer and Topcoat for Genset

3

Primer and Topcoat for Genset - RAL 5010, gentian blue

Name Plates for Complete Engine

3

Name Plates for Aggregate in Russian

Fuel System

Zero-Pressure Gas Control Train

3

Gas train DN 65/65/65 - with seal monitoring unit

Connecting Accessories for Zero Pressure Train

3

Compensator for gasconnection

3

Connection Accessories for Gas Train DN 65 - Steel

Electrical Preheating

3

Electric Preheating - 400 / 480 V / 9 kW / with flanges

3

Counter Flange Set DN 80

Sensors

3

Exhaust back pressure sensor

Genset Management (TEM)

Base System

3

TEM - Basic Cabinet (ST20F-F)

3

TEM packaging in wooden crate (VER)

Power Plant Control System

3

Inlet air preheating (AVW)

Interface

3

Modbus RTU (MRTU)

3

Analog speed setting (ASD)

Hardware

3

I/O Controller (IOC) (included in Base system)

3

Operating terminal (BRT)

3

wall switch cabinet, Height 1200mm door hinge right (AE0R)

3

Console (KBW)

3

Cable entry from above (KEO)

3

TEM connecting cable set 15m (K20ARM15)

Documentation

3

Documentation first language - standard documentation

el.power 1560kW 10500V 50Hz new TPEM

heat utilization temp.power 1597kW

alternator Marelli MJH560LA4 or similar

Genset MWM TCG2020 V16

Technical data

1560 kWel; 10500 V, 50 Hz; Natural gas, MN = 80

Engine / Configuration code:

TCG 2020 V16

R

Speed / Mean piston speed:

[1/min] / [m/s]

1500 / 9.8

Configuration / number of cylinders:

[ - ]

V / 16

Bore / Stroke / Displacement:

[mm]/[mm]/[dm3]

170 / 195 / 71

Compression ratio:

[ - ]

13

Mean effective pressure:

[bar]

18,2

Mean lube oil consumption at full load:

[g/kWh]

0,15

Generator:

Marelli MJH 560 LA4 or similar (*)

Voltage / voltage range / cos Phi:

[V] / [%] / [-]

10500 / 10 / 1

Speed / frequency:

[1/min] / [Hz]

1500 / 50

Engine Parts

3

Engine configuration

3

Basic parts

3

Exhaust gas system

3

Exhaust Gas Outlet vertical

3

Exhaust turbo charger

3

Gas mixture pipe

3

Cooling system on cylinder rows A or B, horizontal

3

Torsional vibration damper

3

Fly wheel

3

Fly wheel casing

3

Starter equipment, electric with double starter and temperature cut-off

3

Engine Mounting

3

Lube oil system

3

Gas mixer

3

Suction system Standard

3

Crankcase ventilation

3

Primer and Topcoat Engine - Primer

3

Conservation

Exhaust Gas Outlet

3

Exhaust Gas Outlet vertical

Engine Control

3

Control without ExhaustTurboCharger speed monitoring / without control exhaust wastegate

Pre-Lubrication

3

Pre lubrication 230 / 400 / 460 V

Engine Test

3

Engine acceptance test without customer participation

Tools for commissioning and assembling

1

Tool Kit small scope for commissioning and assembling

Spare Parts for New Engines

3

without spare parts for new installation

Genset Parts

3

Genset defintion

3

Generator - Marelli - MJH 560 LA4

3

Base frame with integrated oil tank

3

Elastic genset mounting

3

Elastic coupling

3

Fasteners

3

Crankcase ventilation

3

Pre Lubrication Genset - V

3

Lubeoil level monitoring

3

Additional parts for lubrication system 230 V/50 / 60 Hz

3

Warning sign for oil cooler

3

Suction pipe

3

Air filter with air preheating

3

Water circuit components for air preheating

Primer and Topcoat for Genset

3

Primer and Topcoat for Genset - RAL 5010, gentian blue

Name Plates for Complete Engine

3

Name Plates for Aggregate in Russian

Fuel System

Zero-Pressure Gas Control Train

3

Gas train DN 65/65/65 - with seal monitoring unit

Connecting Accessories for Zero Pressure Train

3

Compensator for gasconnection

3

Connection Accessories for Gas Train DN 65 - Steel

Electrical Preheating

3

Electric Preheating - 400 / 480 V / 9 kW / with flanges

3

Counter Flange Set DN 80

Sensors

3

Exhaust back pressure sensor

Genset Management (TEM)

Base System

3

TEM - Basic Cabinet (ST20F-F)

3

TEM packaging in wooden crate (VER)

Power Plant Control System

3

Inlet air preheating (AVW)

Interface

3

Modbus RTU (MRTU)

3

Analog speed setting (ASD)

Hardware

3

I/O Controller (IOC) (included in Base system)

3

Operating terminal (BRT)

3

wall switch cabinet, Height 1200mm door hinge right (AE0R)

3

Console (KBW)

3

Cable entry from above (KEO)

3

TEM connecting cable set 15m (K20ARM15)

Documentation

3

Documentation first language - standard documentation

el.power 1560kW 10500V 50Hz new TPEM

heat utilization temp.power 1597kW

alternator Marelli MJH560LA4 or similar

Genset MWM TCG2020 V16

Technical data

1560 kWel; 10500 V, 50 Hz; Natural gas, MN = 80

Engine / Configuration code:

TCG 2020 V16

R

Speed / Mean piston speed:

[1/min] / [m/s]

1500 / 9.8

Configuration / number of cylinders:

[ - ]

V / 16

Bore / Stroke / Displacement:

[mm]/[mm]/[dm3]

170 / 195 / 71

Compression ratio:

[ - ]

13

Mean effective pressure:

[bar]

18,2

Mean lube oil consumption at full load:

[g/kWh]

0,15

Generator:

Marelli MJH 560 LA4 or similar (*)

Voltage / voltage range / cos Phi:

[V] / [%] / [-]

10500 / 10 / 1

Speed / frequency:

[1/min] / [Hz]

1500 / 50

Engine Parts

3

Engine configuration

3

Basic parts

3

Exhaust gas system

3

Exhaust Gas Outlet vertical

3

Exhaust turbo charger

3

Gas mixture pipe

3

Cooling system on cylinder rows A or B, horizontal

3

Torsional vibration damper

3

Fly wheel

3

Fly wheel casing

3

Starter equipment, electric with double starter and temperature cut-off

3

Engine Mounting

3

Lube oil system

3

Gas mixer

3

Suction system Standard

3

Crankcase ventilation

3

Primer and Topcoat Engine - Primer

3

Conservation

Exhaust Gas Outlet

3

Exhaust Gas Outlet vertical

Engine Control

3

Control without ExhaustTurboCharger speed monitoring / without control exhaust wastegate

Pre-Lubrication

3

Pre lubrication 230 / 400 / 460 V

Engine Test

3

Engine acceptance test without customer participation

Tools for commissioning and assembling

1

Tool Kit small scope for commissioning and assembling

Spare Parts for New Engines

3

without spare parts for new installation

Genset Parts

3

Genset defintion

3

Generator - Marelli - MJH 560 LA4

3

Base frame with integrated oil tank

3

Elastic genset mounting

3

Elastic coupling

3

Fasteners

3

Crankcase ventilation

3

Pre Lubrication Genset - V

3

Lubeoil level monitoring

3

Additional parts for lubrication system 230 V/50 / 60 Hz

3

Warning sign for oil cooler

3

Suction pipe

3

Air filter with air preheating

3

Water circuit components for air preheating

Primer and Topcoat for Genset

3

Primer and Topcoat for Genset - RAL 5010, gentian blue

Name Plates for Complete Engine

3

Name Plates for Aggregate in Russian

Fuel System

Zero-Pressure Gas Control Train

3

Gas train DN 65/65/65 - with seal monitoring unit

Connecting Accessories for Zero Pressure Train

3

Compensator for gasconnection

3

Connection Accessories for Gas Train DN 65 - Steel

Electrical Preheating

3

Electric Preheating - 400 / 480 V / 9 kW / with flanges

3

Counter Flange Set DN 80

Sensors

3

Exhaust back pressure sensor

Genset Management (TEM)

Base System

3

TEM - Basic Cabinet (ST20F-F)

3

TEM packaging in wooden crate (VER)

Power Plant Control System

3

Inlet air preheating (AVW)

Interface

3

Modbus RTU (MRTU)

3

Analog speed setting (ASD)

Hardware

3

I/O Controller (IOC) (included in Base system)

3

Operating terminal (BRT)

3

wall switch cabinet, Height 1200mm door hinge right (AE0R)

3

Console (KBW)

3

Cable entry from above (KEO)

3

TEM connecting cable set 15m (K20ARM15)

Documentation

3

Documentation first language - standard documentation

el.power 1560kW 10500V 50Hz new TPEM

heat utilization temp.power 1597kW

alternator Marelli MJH560LA4 or similar

Genset MWM TCG2020 V16

Technical data

1560 kWel; 10500 V, 50 Hz; Natural gas, MN = 80

Engine / Configuration code:

TCG 2020 V16

R

Speed / Mean piston speed:

[1/min] / [m/s]

1500 / 9.8

Configuration / number of cylinders:

[ - ]

V / 16

Bore / Stroke / Displacement:

[mm]/[mm]/[dm3]

170 / 195 / 71

Compression ratio:

[ - ]

13

Mean effective pressure:

[bar]

18,2

Mean lube oil consumption at full load:

[g/kWh]

0,15

Generator:

Marelli MJH 560 LA4 or similar (*)

Voltage / voltage range / cos Phi:

[V] / [%] / [-]

10500 / 10 / 1

Speed / frequency:

[1/min] / [Hz]

1500 / 50

Engine Parts

3

Engine configuration

3

Basic parts

3

Exhaust gas system

3

Exhaust Gas Outlet vertical

3

Exhaust turbo charger

3

Gas mixture pipe

3

Cooling system on cylinder rows A or B, horizontal

3

Torsional vibration damper

3

Fly wheel

3

Fly wheel casing

3

Starter equipment, electric with double starter and temperature cut-off

3

Engine Mounting

3

Lube oil system

3

Gas mixer

3

Suction system Standard

3

Crankcase ventilation

3

Primer and Topcoat Engine - Primer

3

Conservation

Exhaust Gas Outlet

3

Exhaust Gas Outlet vertical

Engine Control

3

Control without ExhaustTurboCharger speed monitoring / without control exhaust wastegate

Pre-Lubrication

3

Pre lubrication 230 / 400 / 460 V

Engine Test

3

Engine acceptance test without customer participation

Tools for commissioning and assembling

1

Tool Kit small scope for commissioning and assembling

Spare Parts for New Engines

3

without spare parts for new installation

Genset Parts

3

Genset defintion

3

Generator - Marelli - MJH 560 LA4

3

Base frame with integrated oil tank

3

Elastic genset mounting

3

Elastic coupling

3

Fasteners

3

Crankcase ventilation

3

Pre Lubrication Genset - V

3

Lubeoil level monitoring

3

Additional parts for lubrication system 230 V/50 / 60 Hz

3

Warning sign for oil cooler

3

Suction pipe

3

Air filter with air preheating

3

Water circuit components for air preheating

Primer and Topcoat for Genset

3

Primer and Topcoat for Genset - RAL 5010, gentian blue

Name Plates for Complete Engine

3

Name Plates for Aggregate in Russian

Fuel System

Zero-Pressure Gas Control Train

3

Gas train DN 65/65/65 - with seal monitoring unit

Connecting Accessories for Zero Pressure Train

3

Compensator for gasconnection

3

Connection Accessories for Gas Train DN 65 - Steel

Electrical Preheating

3

Electric Preheating - 400 / 480 V / 9 kW / with flanges

3

Counter Flange Set DN 80

Sensors

3

Exhaust back pressure sensor

Genset Management (TEM)

Base System

3

TEM - Basic Cabinet (ST20F-F)

3

TEM packaging in wooden crate (VER)

Power Plant Control System

3

Inlet air preheating (AVW)

Interface

3

Modbus RTU (MRTU)

3

Analog speed setting (ASD)

Hardware

3

I/O Controller (IOC) (included in Base system)

3

Operating terminal (BRT)

3

wall switch cabinet, Height 1200mm door hinge right (AE0R)

3

Console (KBW)

3

Cable entry from above (KEO)

3

TEM connecting cable set 15m (K20ARM15)

Documentation

3

Documentation first language - standard documentation

el.power 1560kW 10500V 50Hz new TPEM

heat utilization temp.power 1597kW

alternator Marelli MJH560LA4 or similar

Genset MWM TCG2020 V16

Technical data

1560 kWel; 10500 V, 50 Hz; Natural gas, MN = 80

Engine / Configuration code:

TCG 2020 V16

R

Speed / Mean piston speed:

[1/min] / [m/s]

1500 / 9.8

Configuration / number of cylinders:

[ - ]

V / 16

Bore / Stroke / Displacement:

[mm]/[mm]/[dm3]

170 / 195 / 71

Compression ratio:

[ - ]

13

Mean effective pressure:

[bar]

18,2

Mean lube oil consumption at full load:

[g/kWh]

0,15

Generator:

Marelli MJH 560 LA4 or similar (*)

Voltage / voltage range / cos Phi:

[V] / [%] / [-]

10500 / 10 / 1

Speed / frequency:

[1/min] / [Hz]

1500 / 50

Engine Parts

3

Engine configuration

3

Basic parts

3

Exhaust gas system

3

Exhaust Gas Outlet vertical

3

Exhaust turbo charger

3

Gas mixture pipe

3

Cooling system on cylinder rows A or B, horizontal

3

Torsional vibration damper

3

Fly wheel

3

Fly wheel casing

3

Starter equipment, electric with double starter and temperature cut-off

3

Engine Mounting

3

Lube oil system

3

Gas mixer

3

Suction system Standard

3

Crankcase ventilation

3

Primer and Topcoat Engine - Primer

3

Conservation

Exhaust Gas Outlet

3

Exhaust Gas Outlet vertical

Engine Control

3

Control without ExhaustTurboCharger speed monitoring / without control exhaust wastegate

Pre-Lubrication

3

Pre lubrication 230 / 400 / 460 V

Engine Test

3

Engine acceptance test without customer participation

Tools for commissioning and assembling

1

Tool Kit small scope for commissioning and assembling

Spare Parts for New Engines

3

without spare parts for new installation

Genset Parts

3

Genset defintion

3

Generator - Marelli - MJH 560 LA4

3

Base frame with integrated oil tank

3

Elastic genset mounting

3

Elastic coupling

3

Fasteners

3

Crankcase ventilation

3

Pre Lubrication Genset - V

3

Lubeoil level monitoring

3

Additional parts for lubrication system 230 V/50 / 60 Hz

3

Warning sign for oil cooler

3

Suction pipe

3

Air filter with air preheating

3

Water circuit components for air preheating

Primer and Topcoat for Genset

3

Primer and Topcoat for Genset - RAL 5010, gentian blue

Name Plates for Complete Engine

3

Name Plates for Aggregate in Russian

Fuel System

Zero-Pressure Gas Control Train

3

Gas train DN 65/65/65 - with seal monitoring unit

Connecting Accessories for Zero Pressure Train

3

Compensator for gasconnection

3

Connection Accessories for Gas Train DN 65 - Steel

Electrical Preheating

3

Electric Preheating - 400 / 480 V / 9 kW / with flanges

3

Counter Flange Set DN 80

Sensors

3

Exhaust back pressure sensor

Genset Management (TEM)

Base System

3

TEM - Basic Cabinet (ST20F-F)

3

TEM packaging in wooden crate (VER)

Power Plant Control System

3

Inlet air preheating (AVW)

Interface

3

Modbus RTU (MRTU)

3

Analog speed setting (ASD)

Hardware

3

I/O Controller (IOC) (included in Base system)

3

Operating terminal (BRT)

3

wall switch cabinet, Height 1200mm door hinge right (AE0R)

3

Console (KBW)

3

Cable entry from above (KEO)

3

TEM connecting cable set 15m (K20ARM15)

Documentation

3

Documentation first language - standard documentation

el.power 1560kW 10500V 50Hz new TPEM

heat utilization temp.power 1597kW

alternator Marelli MJH560LA4 or similar

Genset MWM TCG2020 V16

Technical data

1560 kWel; 10500 V, 50 Hz; Natural gas, MN = 80

Engine / Configuration code:

TCG 2020 V16

R

Speed / Mean piston speed:

[1/min] / [m/s]

1500 / 9.8

Configuration / number of cylinders:

[ - ]

V / 16

Bore / Stroke / Displacement:

[mm]/[mm]/[dm3]

170 / 195 / 71

Compression ratio:

[ - ]

13

Mean effective pressure:

[bar]

18,2

Mean lube oil consumption at full load:

[g/kWh]

0,15

Generator:

Marelli MJH 560 LA4 or similar (*)

Voltage / voltage range / cos Phi:

[V] / [%] / [-]

10500 / 10 / 1

Speed / frequency:

[1/min] / [Hz]

1500 / 50

Engine Parts

3

Engine configuration

3

Basic parts

3

Exhaust gas system

3

Exhaust Gas Outlet vertical

3

Exhaust turbo charger

3

Gas mixture pipe

3

Cooling system on cylinder rows A or B, horizontal

3

Torsional vibration damper

3

Fly wheel

3

Fly wheel casing

3

Starter equipment, electric with double starter and temperature cut-off

3

Engine Mounting

3

Lube oil system

3

Gas mixer

3

Suction system Standard

3

Crankcase ventilation

3

Primer and Topcoat Engine - Primer

3

Conservation

Exhaust Gas Outlet

3

Exhaust Gas Outlet vertical

Engine Control

3

Control without ExhaustTurboCharger speed monitoring / without control exhaust wastegate

Pre-Lubrication

3

Pre lubrication 230 / 400 / 460 V

Engine Test

3

Engine acceptance test without customer participation

Tools for commissioning and assembling

1

Tool Kit small scope for commissioning and assembling

Spare Parts for New Engines

3

without spare parts for new installation

Genset Parts

3

Genset defintion

3

Generator - Marelli - MJH 560 LA4

3

Base frame with integrated oil tank

3

Elastic genset mounting

3

Elastic coupling

3

Fasteners

3

Crankcase ventilation

3

Pre Lubrication Genset - V

3

Lubeoil level monitoring

3

Additional parts for lubrication system 230 V/50 / 60 Hz

3

Warning sign for oil cooler

3

Suction pipe

3

Air filter with air preheating

3

Water circuit components for air preheating

Primer and Topcoat for Genset

3

Primer and Topcoat for Genset - RAL 5010, gentian blue

Name Plates for Complete Engine

3

Name Plates for Aggregate in Russian

Fuel System

Zero-Pressure Gas Control Train

3

Gas train DN 65/65/65 - with seal monitoring unit

Connecting Accessories for Zero Pressure Train

3

Compensator for gasconnection

3

Connection Accessories for Gas Train DN 65 - Steel

Electrical Preheating

3

Electric Preheating - 400 / 480 V / 9 kW / with flanges

3

Counter Flange Set DN 80

Sensors

3

Exhaust back pressure sensor

Genset Management (TEM)

Base System

3

TEM - Basic Cabinet (ST20F-F)

3

TEM packaging in wooden crate (VER)

Power Plant Control System

3

Inlet air preheating (AVW)

Interface

3

Modbus RTU (MRTU)

3

Analog speed setting (ASD)

Hardware

3

I/O Controller (IOC) (included in Base system)

3

Operating terminal (BRT)

3

wall switch cabinet, Height 1200mm door hinge right (AE0R)

3

Console (KBW)

3

Cable entry from above (KEO)

3

TEM connecting cable set 15m (K20ARM15)

Documentation

3

Documentation first language - standard documentation

el.power 1560kW 10500V 50Hz new TPEM

heat utilization temp.power 1597kW

alternator Marelli MJH560LA4 or similar

Genset MWM TCG2020 V16

Technical data

1560 kWel; 10500 V, 50 Hz; Natural gas, MN = 80

Engine / Configuration code:

TCG 2020 V16

R

Speed / Mean piston speed:

[1/min] / [m/s]

1500 / 9.8

Configuration / number of cylinders:

[ - ]

V / 16

Bore / Stroke / Displacement:

[mm]/[mm]/[dm3]

170 / 195 / 71

Compression ratio:

[ - ]

13

Mean effective pressure:

[bar]

18,2

Mean lube oil consumption at full load:

[g/kWh]

0,15

Generator:

Marelli MJH 560 LA4 or similar (*)

Voltage / voltage range / cos Phi:

[V] / [%] / [-]

10500 / 10 / 1

Speed / frequency:

[1/min] / [Hz]

1500 / 50

Engine Parts

3

Engine configuration

3

Basic parts

3

Exhaust gas system

3

Exhaust Gas Outlet vertical

3

Exhaust turbo charger

3

Gas mixture pipe

3

Cooling system on cylinder rows A or B, horizontal

3

Torsional vibration damper

3

Fly wheel

3

Fly wheel casing

3

Starter equipment, electric with double starter and temperature cut-off

3

Engine Mounting

3

Lube oil system

3

Gas mixer

3

Suction system Standard

3

Crankcase ventilation

3

Primer and Topcoat Engine - Primer

3

Conservation

Exhaust Gas Outlet

3

Exhaust Gas Outlet vertical

Engine Control

3

Control without ExhaustTurboCharger speed monitoring / without control exhaust wastegate

Pre-Lubrication

3

Pre lubrication 230 / 400 / 460 V

Engine Test

3

Engine acceptance test without customer participation

Tools for commissioning and assembling

1

Tool Kit small scope for commissioning and assembling

Spare Parts for New Engines

3

without spare parts for new installation

Genset Parts

3

Genset defintion

3

Generator - Marelli - MJH 560 LA4

3

Base frame with integrated oil tank

3

Elastic genset mounting

3

Elastic coupling

3

Fasteners

3

Crankcase ventilation

3

Pre Lubrication Genset - V

3

Lubeoil level monitoring

3

Additional parts for lubrication system 230 V/50 / 60 Hz

3

Warning sign for oil cooler

3

Suction pipe

3

Air filter with air preheating

3

Water circuit components for air preheating

Primer and Topcoat for Genset

3

Primer and Topcoat for Genset - RAL 5010, gentian blue

Name Plates for Complete Engine

3

Name Plates for Aggregate in Russian

Fuel System

Zero-Pressure Gas Control Train

3

Gas train DN 65/65/65 - with seal monitoring unit

Connecting Accessories for Zero Pressure Train

3

Compensator for gasconnection

3

Connection Accessories for Gas Train DN 65 - Steel

Electrical Preheating

3

Electric Preheating - 400 / 480 V / 9 kW / with flanges

3

Counter Flange Set DN 80

Sensors

3

Exhaust back pressure sensor

Genset Management (TEM)

Base System

3

TEM - Basic Cabinet (ST20F-F)

3

TEM packaging in wooden crate (VER)

Power Plant Control System

3

Inlet air preheating (AVW)

Interface

3

Modbus RTU (MRTU)

3

Analog speed setting (ASD)

Hardware

3

I/O Controller (IOC) (included in Base system)

3

Operating terminal (BRT)

3

wall switch cabinet, Height 1200mm door hinge right (AE0R)

3

Console (KBW)

3

Cable entry from above (KEO)

3

TEM connecting cable set 15m (K20ARM15)

Documentation

3

Documentation first language - standard documentation

el.power 1560kW 10500V 50Hz new TPEM

heat utilization temp.power 1597kW

alternator Marelli MJH560LA4 or similar

Genset MWM TCG2020 V16

Technical data

1560 kWel; 10500 V, 50 Hz; Natural gas, MN = 80

Engine / Configuration code:

TCG 2020 V16

R

Speed / Mean piston speed:

[1/min] / [m/s]

1500 / 9.8

Configuration / number of cylinders:

[ - ]

V / 16

Bore / Stroke / Displacement:

[mm]/[mm]/[dm3]

170 / 195 / 71

Compression ratio:

[ - ]

13

Mean effective pressure:

[bar]

18,2

Mean lube oil consumption at full load:

[g/kWh]

0,15

Generator:

Marelli MJH 560 LA4 or similar (*)

Voltage / voltage range / cos Phi:

[V] / [%] / [-]

10500 / 10 / 1

Speed / frequency:

[1/min] / [Hz]

1500 / 50

Engine Parts

3

Engine configuration

3

Basic parts

3

Exhaust gas system

3

Exhaust Gas Outlet vertical

3

Exhaust turbo charger

3

Gas mixture pipe

3

Cooling system on cylinder rows A or B, horizontal

3

Torsional vibration damper

3

Fly wheel

3

Fly wheel casing

3

Starter equipment, electric with double starter and temperature cut-off

3

Engine Mounting

3

Lube oil system

3

Gas mixer

3

Suction system Standard

3

Crankcase ventilation

3

Primer and Topcoat Engine - Primer

3

Conservation

Exhaust Gas Outlet

3

Exhaust Gas Outlet vertical

Engine Control

3

Control without ExhaustTurboCharger speed monitoring / without control exhaust wastegate

Pre-Lubrication

3

Pre lubrication 230 / 400 / 460 V

Engine Test

3

Engine acceptance test without customer participation

Tools for commissioning and assembling

1

Tool Kit small scope for commissioning and assembling

Spare Parts for New Engines

3

without spare parts for new installation

Genset Parts

3

Genset defintion

3

Generator - Marelli - MJH 560 LA4

3

Base frame with integrated oil tank

3

Elastic genset mounting

3

Elastic coupling

3

Fasteners

3

Crankcase ventilation

3

Pre Lubrication Genset - V

3

Lubeoil level monitoring

3

Additional parts for lubrication system 230 V/50 / 60 Hz

3

Warning sign for oil cooler

3

Suction pipe

3

Air filter with air preheating

3

Water circuit components for air preheating

Primer and Topcoat for Genset

3

Primer and Topcoat for Genset - RAL 5010, gentian blue

Name Plates for Complete Engine

3

Name Plates for Aggregate in Russian

Fuel System

Zero-Pressure Gas Control Train

3

Gas train DN 65/65/65 - with seal monitoring unit

Connecting Accessories for Zero Pressure Train

3

Compensator for gasconnection

3

Connection Accessories for Gas Train DN 65 - Steel

Electrical Preheating

3

Electric Preheating - 400 / 480 V / 9 kW / with flanges

3

Counter Flange Set DN 80

Sensors

3

Exhaust back pressure sensor

Genset Management (TEM)

Base System

3

TEM - Basic Cabinet (ST20F-F)

3

TEM packaging in wooden crate (VER)

Power Plant Control System

3

Inlet air preheating (AVW)

Interface

3

Modbus RTU (MRTU)

3

Analog speed setting (ASD)

Hardware

3

I/O Controller (IOC) (included in Base system)

3

Operating terminal (BRT)

3

wall switch cabinet, Height 1200mm door hinge right (AE0R)

3

Console (KBW)

3

Cable entry from above (KEO)

3

TEM connecting cable set 15m (K20ARM15)

Documentation

3

Documentation first language - standard documentation

el.power 1560kW 10500V 50Hz new TPEM

heat utilization temp.power 1597kW

alternator Marelli MJH560LA4 or similar

Genset MWM TCG2020 V16

Technical data

1560 kWel; 10500 V, 50 Hz; Natural gas, MN = 80

Engine / Configuration code:

TCG 2020 V16

R

Speed / Mean piston speed:

[1/min] / [m/s]

1500 / 9.8

Configuration / number of cylinders:

[ - ]

V / 16

Bore / Stroke / Displacement:

[mm]/[mm]/[dm3]

170 / 195 / 71

Compression ratio:

[ - ]

13

Mean effective pressure:

[bar]

18,2

Mean lube oil consumption at full load:

[g/kWh]

0,15

Generator:

Marelli MJH 560 LA4 or similar (*)

Voltage / voltage range / cos Phi:

[V] / [%] / [-]

10500 / 10 / 1

Speed / frequency:

[1/min] / [Hz]

1500 / 50

Engine Parts

3

Engine configuration

3

Basic parts

3

Exhaust gas system

3

Exhaust Gas Outlet vertical

3

Exhaust turbo charger

3

Gas mixture pipe

3

Cooling system on cylinder rows A or B, horizontal

3

Torsional vibration damper

3

Fly wheel

3

Fly wheel casing

3

Starter equipment, electric with double starter and temperature cut-off

3

Engine Mounting

3

Lube oil system

3

Gas mixer

3

Suction system Standard

3

Crankcase ventilation

3

Primer and Topcoat Engine - Primer

3

Conservation

Exhaust Gas Outlet

3

Exhaust Gas Outlet vertical

Engine Control

3

Control without ExhaustTurboCharger speed monitoring / without control exhaust wastegate

Pre-Lubrication

3

Pre lubrication 230 / 400 / 460 V

Engine Test

3

Engine acceptance test without customer participation

Tools for commissioning and assembling

1

Tool Kit small scope for commissioning and assembling

Spare Parts for New Engines

3

without spare parts for new installation

Genset Parts

3

Genset defintion

3

Generator - Marelli - MJH 560 LA4

3

Base frame with integrated oil tank

3

Elastic genset mounting

3

Elastic coupling

3

Fasteners

3

Crankcase ventilation

3

Pre Lubrication Genset - V

3

Lubeoil level monitoring

3

Additional parts for lubrication system 230 V/50 / 60 Hz

3

Warning sign for oil cooler

3

Suction pipe

3

Air filter with air preheating

3

Water circuit components for air preheating

Primer and Topcoat for Genset

3

Primer and Topcoat for Genset - RAL 5010, gentian blue

Name Plates for Complete Engine

3

Name Plates for Aggregate in Russian

Fuel System

Zero-Pressure Gas Control Train

3

Gas train DN 65/65/65 - with seal monitoring unit

Connecting Accessories for Zero Pressure Train

3

Compensator for gasconnection

3

Connection Accessories for Gas Train DN 65 - Steel

Electrical Preheating

3

Electric Preheating - 400 / 480 V / 9 kW / with flanges

3

Counter Flange Set DN 80

Sensors

3

Exhaust back pressure sensor

Genset Management (TEM)

Base System

3

TEM - Basic Cabinet (ST20F-F)

3

TEM packaging in wooden crate (VER)

Power Plant Control System

3

Inlet air preheating (AVW)

Interface

3

Modbus RTU (MRTU)

3

Analog speed setting (ASD)

Hardware

3

I/O Controller (IOC) (included in Base system)

3

Operating terminal (BRT)

3

wall switch cabinet, Height 1200mm door hinge right (AE0R)

3

Console (KBW)

3

Cable entry from above (KEO)

3

TEM connecting cable set 15m (K20ARM15)

Documentation

3

Documentation first language - standard documentation

el.power 1560kW 10500V 50Hz new TPEM

heat utilization temp.power 1597kW

alternator Marelli MJH560LA4 or similar

Genset MWM TCG2020 V16

Technical data

1560 kWel; 10500 V, 50 Hz; Natural gas, MN = 80

Engine / Configuration code:

TCG 2020 V16

R

Speed / Mean piston speed:

[1/min] / [m/s]

1500 / 9.8

Configuration / number of cylinders:

[ - ]

V / 16

Bore / Stroke / Displacement:

[mm]/[mm]/[dm3]

170 / 195 / 71

Compression ratio:

[ - ]

13

Mean effective pressure:

[bar]

18,2

Mean lube oil consumption at full load:

[g/kWh]

0,15

Generator:

Marelli MJH 560 LA4 or similar (*)

Voltage / voltage range / cos Phi:

[V] / [%] / [-]

10500 / 10 / 1

Speed / frequency:

[1/min] / [Hz]

1500 / 50

Engine Parts

3

Engine configuration

3

Basic parts

3

Exhaust gas system

3

Exhaust Gas Outlet vertical

3

Exhaust turbo charger

3

Gas mixture pipe

3

Cooling system on cylinder rows A or B, horizontal

3

Torsional vibration damper

3

Fly wheel

3

Fly wheel casing

3

Starter equipment, electric with double starter and temperature cut-off

3

Engine Mounting

3

Lube oil system

3

Gas mixer

3

Suction system Standard

3

Crankcase ventilation

3

Primer and Topcoat Engine - Primer

3

Conservation

Exhaust Gas Outlet

3

Exhaust Gas Outlet vertical

Engine Control

3

Control without ExhaustTurboCharger speed monitoring / without control exhaust wastegate

Pre-Lubrication

3

Pre lubrication 230 / 400 / 460 V

Engine Test

3

Engine acceptance test without customer participation

Tools for commissioning and assembling

1

Tool Kit small scope for commissioning and assembling

Spare Parts for New Engines

3

without spare parts for new installation

Genset Parts

3

Genset defintion

3

Generator - Marelli - MJH 560 LA4

3

Base frame with integrated oil tank

3

Elastic genset mounting

3

Elastic coupling

3

Fasteners

3

Crankcase ventilation

3

Pre Lubrication Genset - V

3

Lubeoil level monitoring

3

Additional parts for lubrication system 230 V/50 / 60 Hz

3

Warning sign for oil cooler

3

Suction pipe

3

Air filter with air preheating

3

Water circuit components for air preheating

Primer and Topcoat for Genset

3

Primer and Topcoat for Genset - RAL 5010, gentian blue

Name Plates for Complete Engine

3

Name Plates for Aggregate in Russian

Fuel System

Zero-Pressure Gas Control Train

3

Gas train DN 65/65/65 - with seal monitoring unit

Connecting Accessories for Zero Pressure Train

3

Compensator for gasconnection

3

Connection Accessories for Gas Train DN 65 - Steel

Electrical Preheating

3

Electric Preheating - 400 / 480 V / 9 kW / with flanges

3

Counter Flange Set DN 80

Sensors

3

Exhaust back pressure sensor

Genset Management (TEM)

Base System

3

TEM - Basic Cabinet (ST20F-F)

3

TEM packaging in wooden crate (VER)

Power Plant Control System

3

Inlet air preheating (AVW)

Interface

3

Modbus RTU (MRTU)

3

Analog speed setting (ASD)

Hardware

3

I/O Controller (IOC) (included in Base system)

3

Operating terminal (BRT)

3

wall switch cabinet, Height 1200mm door hinge right (AE0R)

3

Console (KBW)

3

Cable entry from above (KEO)

3

TEM connecting cable set 15m (K20ARM15)

Documentation

3

Documentation first language - standard documentation

el.power 1560kW 10500V 50Hz new TPEM

heat utilization temp.power 1597kW

alternator Marelli MJH560LA4 or similar

Genset MWM TCG2020 V16

Technical data

1560 kWel; 10500 V, 50 Hz; Natural gas, MN = 80

Engine / Configuration code:

TCG 2020 V16

R

Speed / Mean piston speed:

[1/min] / [m/s]

1500 / 9.8

Configuration / number of cylinders:

[ - ]

V / 16

Bore / Stroke / Displacement:

[mm]/[mm]/[dm3]

170 / 195 / 71

Compression ratio:

[ - ]

13

Mean effective pressure:

[bar]

18,2

Mean lube oil consumption at full load:

[g/kWh]

0,15

Generator:

Marelli MJH 560 LA4 or similar (*)

Voltage / voltage range / cos Phi:

[V] / [%] / [-]

10500 / 10 / 1

Speed / frequency:

[1/min] / [Hz]

1500 / 50

Engine Parts

3

Engine configuration

3

Basic parts

3

Exhaust gas system

3

Exhaust Gas Outlet vertical

3

Exhaust turbo charger

3

Gas mixture pipe

3

Cooling system on cylinder rows A or B, horizontal

3

Torsional vibration damper

3

Fly wheel

3

Fly wheel casing

3

Starter equipment, electric with double starter and temperature cut-off

3

Engine Mounting

3

Lube oil system

3

Gas mixer

3

Suction system Standard

3

Crankcase ventilation

3

Primer and Topcoat Engine - Primer

3

Conservation

Exhaust Gas Outlet

3

Exhaust Gas Outlet vertical

Engine Control

3

Control without ExhaustTurboCharger speed monitoring / without control exhaust wastegate

Pre-Lubrication

3

Pre lubrication 230 / 400 / 460 V

Engine Test

3

Engine acceptance test without customer participation

Tools for commissioning and assembling

1

Tool Kit small scope for commissioning and assembling

Spare Parts for New Engines

3

without spare parts for new installation

Genset Parts

3

Genset defintion

3

Generator - Marelli - MJH 560 LA4

3

Base frame with integrated oil tank

3

Elastic genset mounting

3

Elastic coupling

3

Fasteners

3

Crankcase ventilation

3

Pre Lubrication Genset - V

3

Lubeoil level monitoring

3

Additional parts for lubrication system 230 V/50 / 60 Hz

3

Warning sign for oil cooler

3

Suction pipe

3

Air filter with air preheating

3

Water circuit components for air preheating

Primer and Topcoat for Genset

3

Primer and Topcoat for Genset - RAL 5010, gentian blue

Name Plates for Complete Engine

3

Name Plates for Aggregate in Russian

Fuel System

Zero-Pressure Gas Control Train

3

Gas train DN 65/65/65 - with seal monitoring unit

Connecting Accessories for Zero Pressure Train

3

Compensator for gasconnection

3

Connection Accessories for Gas Train DN 65 - Steel

Electrical Preheating

3

Electric Preheating - 400 / 480 V / 9 kW / with flanges

3

Counter Flange Set DN 80

Sensors

3

Exhaust back pressure sensor

Genset Management (TEM)

Base System

3

TEM - Basic Cabinet (ST20F-F)

3

TEM packaging in wooden crate (VER)

Power Plant Control System

3

Inlet air preheating (AVW)

Interface

3

Modbus RTU (MRTU)

3

Analog speed setting (ASD)

Hardware

3

I/O Controller (IOC) (included in Base system)

3

Operating terminal (BRT)

3

wall switch cabinet, Height 1200mm door hinge right (AE0R)

3

Console (KBW)

3

Cable entry from above (KEO)

3

TEM connecting cable set 15m (K20ARM15)

Documentation

3

Documentation first language - standard documentation

el.power 1560kW 10500V 50Hz new TPEM

heat utilization temp.power 1597kW

alternator Marelli MJH560LA4 or similar

Genset MWM TCG2020 V16

Technical data

1560 kWel; 10500 V, 50 Hz; Natural gas, MN = 80

Engine / Configuration code:

TCG 2020 V16

R

Speed / Mean piston speed:

[1/min] / [m/s]

1500 / 9.8

Configuration / number of cylinders:

[ - ]

V / 16

Bore / Stroke / Displacement:

[mm]/[mm]/[dm3]

170 / 195 / 71

Compression ratio:

[ - ]

13

Mean effective pressure:

[bar]

18,2

Mean lube oil consumption at full load:

[g/kWh]

0,15

Generator:

Marelli MJH 560 LA4 or similar (*)

Voltage / voltage range / cos Phi:

[V] / [%] / [-]

10500 / 10 / 1

Speed / frequency:

[1/min] / [Hz]

1500 / 50

Engine Parts

3

Engine configuration

3

Basic parts

3

Exhaust gas system

3

Exhaust Gas Outlet vertical

3

Exhaust turbo charger

3

Gas mixture pipe

3

Cooling system on cylinder rows A or B, horizontal

3

Torsional vibration damper

3

Fly wheel

3

Fly wheel casing

3

Starter equipment, electric with double starter and temperature cut-off

3

Engine Mounting

3

Lube oil system

3

Gas mixer

3

Suction system Standard

3

Crankcase ventilation

3

Primer and Topcoat Engine - Primer

3

Conservation

Exhaust Gas Outlet

3

Exhaust Gas Outlet vertical

Engine Control

3

Control without ExhaustTurboCharger speed monitoring / without control exhaust wastegate

Pre-Lubrication

3

Pre lubrication 230 / 400 / 460 V

Engine Test

3

Engine acceptance test without customer participation

Tools for commissioning and assembling

1

Tool Kit small scope for commissioning and assembling

Spare Parts for New Engines

3

without spare parts for new installation

Genset Parts

3

Genset defintion

3

Generator - Marelli - MJH 560 LA4

3

Base frame with integrated oil tank

3

Elastic genset mounting

3

Elastic coupling

3

Fasteners

3

Crankcase ventilation

3

Pre Lubrication Genset - V

3

Lubeoil level monitoring

3

Additional parts for lubrication system 230 V/50 / 60 Hz

3

Warning sign for oil cooler

3

Suction pipe

3

Air filter with air preheating

3

Water circuit components for air preheating

Primer and Topcoat for Genset

3

Primer and Topcoat for Genset - RAL 5010, gentian blue

Name Plates for Complete Engine

3

Name Plates for Aggregate in Russian

Fuel System

Zero-Pressure Gas Control Train

3

Gas train DN 65/65/65 - with seal monitoring unit

Connecting Accessories for Zero Pressure Train

3

Compensator for gasconnection

3

Connection Accessories for Gas Train DN 65 - Steel

Electrical Preheating

3

Electric Preheating - 400 / 480 V / 9 kW / with flanges

3

Counter Flange Set DN 80

Sensors

3

Exhaust back pressure sensor

Genset Management (TEM)

Base System

3

TEM - Basic Cabinet (ST20F-F)

3

TEM packaging in wooden crate (VER)

Power Plant Control System

3

Inlet air preheating (AVW)

Interface

3

Modbus RTU (MRTU)

3

Analog speed setting (ASD)

Hardware

3

I/O Controller (IOC) (included in Base system)

3

Operating terminal (BRT)

3

wall switch cabinet, Height 1200mm door hinge right (AE0R)

3

Console (KBW)

3

Cable entry from above (KEO)

3

TEM connecting cable set 15m (K20ARM15)

Documentation

3

Documentation first language - standard documentation

el.power 1560kW 10500V 50Hz new TPEM

heat utilization temp.power 1597kW

alternator Marelli MJH560LA4 or similar

Genset MWM TCG2020 V16

Technical data

1560 kWel; 10500 V, 50 Hz; Natural gas, MN = 80

Engine / Configuration code:

TCG 2020 V16

R

Speed / Mean piston speed:

[1/min] / [m/s]

1500 / 9.8

Configuration / number of cylinders:

[ - ]

V / 16

Bore / Stroke / Displacement:

[mm]/[mm]/[dm3]

170 / 195 / 71

Compression ratio:

[ - ]

13

Mean effective pressure:

[bar]

18,2

Mean lube oil consumption at full load:

[g/kWh]

0,15

Generator:

Marelli MJH 560 LA4 or similar (*)

Voltage / voltage range / cos Phi:

[V] / [%] / [-]

10500 / 10 / 1

Speed / frequency:

[1/min] / [Hz]

1500 / 50

Engine Parts

3

Engine configuration

3

Basic parts

3

Exhaust gas system

3

Exhaust Gas Outlet vertical

3

Exhaust turbo charger

3

Gas mixture pipe

3

Cooling system on cylinder rows A or B, horizontal

3

Torsional vibration damper

3

Fly wheel

3

Fly wheel casing

3

Starter equipment, electric with double starter and temperature cut-off

3

Engine Mounting

3